Copyright © Luohe (Wuxi) fluid control Co., Ltd All rights reserved.

ICP2021014876

Copyright © Luohe (Wuxi) fluid control Co., Ltd All rights reserved.

ICP2021014876

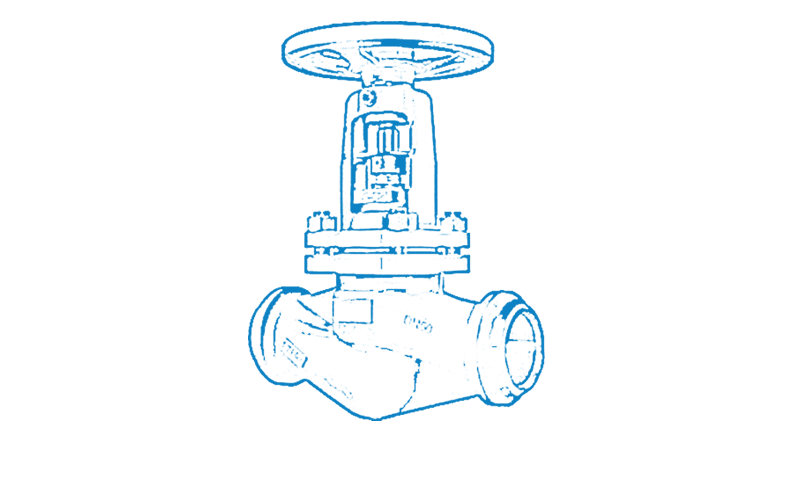

Forged steel bellows globe valve

Bellows globe valve is made of new non-metallic materials. It can withstand long-term high temperature and high pressure without losing elasticity. Moreover, the contact area between plunger and sealing ring is large. The sealing ring is made of mixed materials with good performance, reliable sealing and durable. It is mainly used in metallurgy, electric power, chemical industry, oil refining, chemical fertilizer, light industry, food and other industries.

Structural features

1. the product structure is reasonable, reliable sealing, excellent performance, beautiful shape.

2. Sealing surface surfacing CO based cemented carbide, wear resistance, corrosion resistance, abrasion resistance, long service life.

3. the valve stem by quenching and surface nitriding treatment, has good corrosion resistance and abrasion resistance.

4. the valve is equipped with inverted sealing structure, sealing is reliable.

5. the parts material and flange size can be reasonably selected according to the actual working conditions or user requirements, to meet various engineering needs.

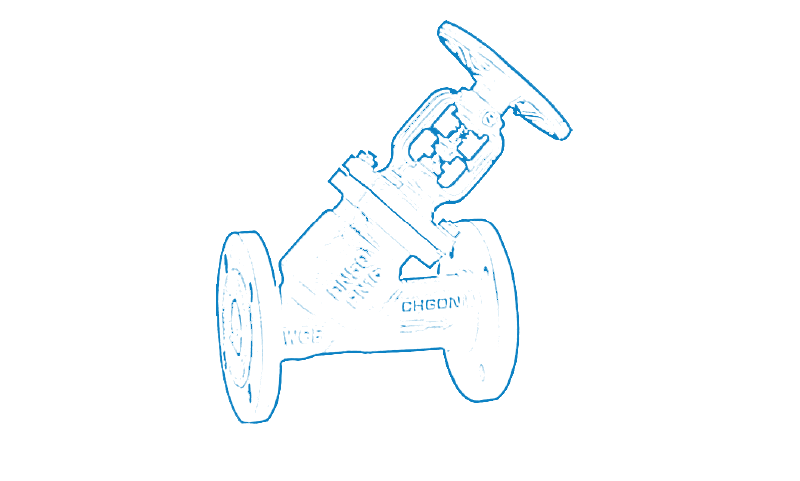

Welded bellows globe valve

Welded bellows globe valves are used in steam systems, natural gas, toxic waste gas purification, vacuum units, hot oil systems, heating equipment, refrigeration systems, ammonia, hot water, power stations, etc.

Structural features

1. Double sealing design (bellows + packing) If bellows fail, stem packing can be avoided.

2. Reasonable structure, reliable sealing, excellent performance, beautiful shape.

3. No fluid loss, reduce energy loss and improve plant equipment safety.

4. Sealing surface surfacing of CO based cemented carbide, wear resistance, corrosion resistance, good friction resistance, long service life, reduce the number of maintenance, reduce operating costs.

5. Rigid and durable bellows seal design ensures zero leakage of valve stem and provides conditions without maintenance.

6. Stop valve stem quenching and surface nitriding treatment, with good anti-corrosion and anti-friction properties;

7. Stem lifting position indication is more intuitive.

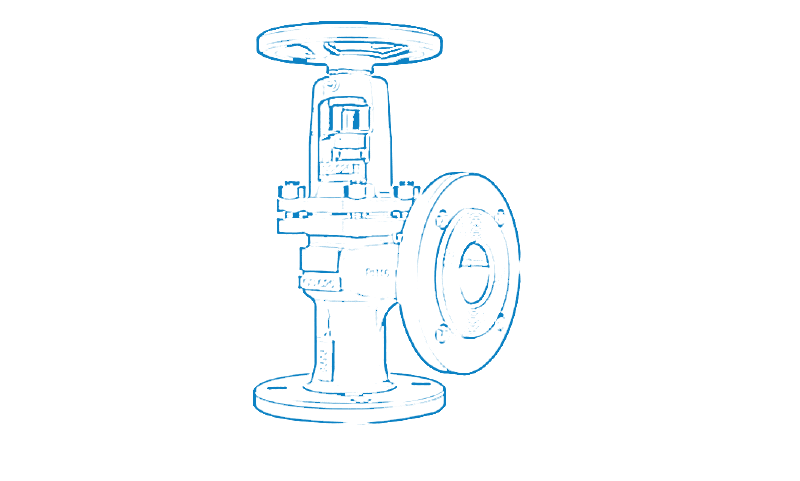

Bevel bellows golobe valve

The bevel bellows globe valve adopts double sealing design (bellows + packing) if the bellows fail, the bevel bellows globe valve stem quenching and surface nitriding treatment, has good anti-corrosion and anti-friction performance;The rugged bellows seal design of the bevel bellows globe valve ensures zero leakage of the stem and provides maintenance-free conditions.

Structural features

1. Double sealing design (bellows + packing) If bellows fail, stem packing can be avoided.

2. Reasonable structure, reliable sealing, excellent performance, beautiful shape.

3. No fluid loss, reduce energy loss and improve plant equipment safety.

4. Sealing surface surfacing of CO based cemented carbide, wear resistance, corrosion resistance, good friction resistance, long service life, reduce the number of maintenance, reduce operating costs.

5. Rigid and durable bellows seal design ensures zero leakage of valve stem and provides conditions without maintenance.

6. Stop valve stem quenching and surface nitriding treatment, with good anti-corrosion and anti-friction properties;

7. Stem lifting position indication is more intuitive.

Right Angle bellows globe valve

Right-angle bellows globe valve is installed on the steam pipe, with bellows as the stem sealing element, can make the stem parts without leakage, to prevent the steam leakage of the globe valve.It is the ideal valve for boiler steam.No fluid loss improves energy efficiency, increases safety of production equipment, reduces maintenance costs, frequent maintenance reduces operating costs, and provides a clean and safe working environment.

Structural features

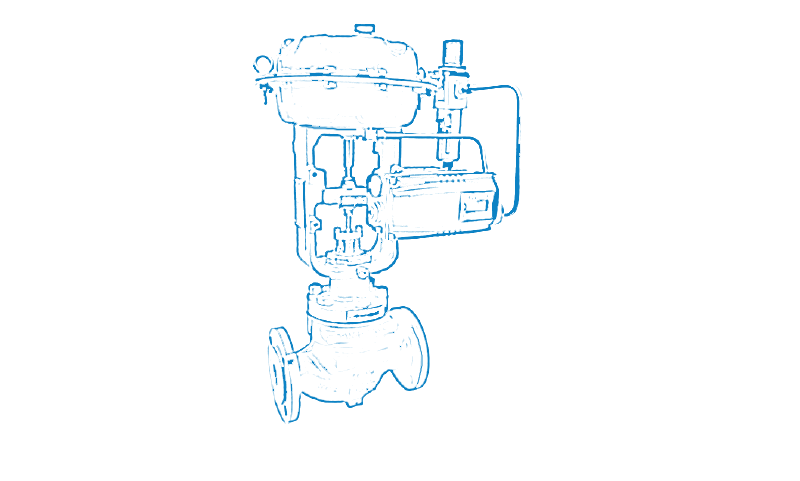

Pneumatic bellows globe valve

Pneumatic bellows globe valve adopts double acting cylinder, using upper chamber or lower chamber intake to remotely control the valve, easy to operate and flexible.Cylinder medium: compressed air, nitrogen.Simple structure, convenient manufacture and maintenance;Small working stroke, short opening and closing time;Closing body (valve disc) and valve seat sealing surface adopts cone sealing, closing force is small, erosion resistance, reliable sealing.The valve seat can be a replacement type valve seat, which can be combined with the sealing surface material of the closing part arbitrarily to meet the requirements of working conditions and prolong the service life.

Structural features

1. The product has reasonable structure, reliable sealing, excellent performance and beautiful shape;

2. Sealing surface surfacing CO cemented carbide, wear resistance, corrosion resistance, good resistance to friction, long service life;

3. Valve stem quenching and surface nitriding treatment, with good anti-corrosion and anti-friction properties;

4. Double sealing, more reliable performance;

5. Stem lifting position indication is more intuitive;

6. Parts materials, flange and butt-welding size can be reasonably selected according to actual working conditions or user requirements to meet various engineering needs.