Copyright © Luohe (Wuxi) fluid control Co., Ltd All rights reserved.

ICP2021014876

Copyright © Luohe (Wuxi) fluid control Co., Ltd All rights reserved.

ICP2021014876

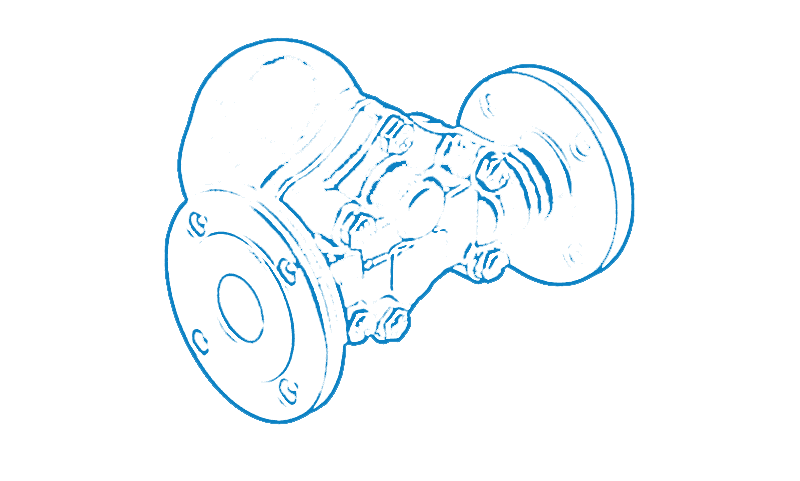

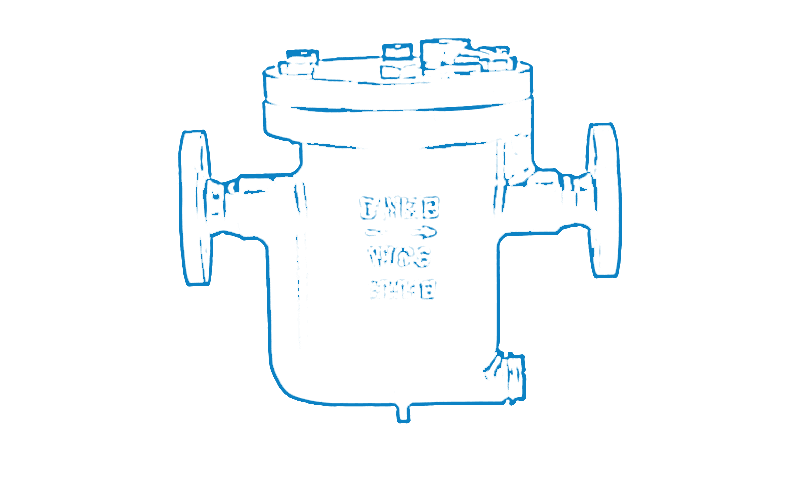

Free float steam trap

UOUK float trap is operated by using the density difference between steam and condensate.This type of trap is very convenient to operate and can work effectively when the condensate load changes, while not affected by sudden changes in operating pressure.The trap has a large displacement relative to its size, up to 150,000kg/h, and can be discharged immediately as condensate is generated.Because of this characteristic, the trap is an ideal choice for steam control equipment.The maximum working pressure of the trap is up to 80bar.

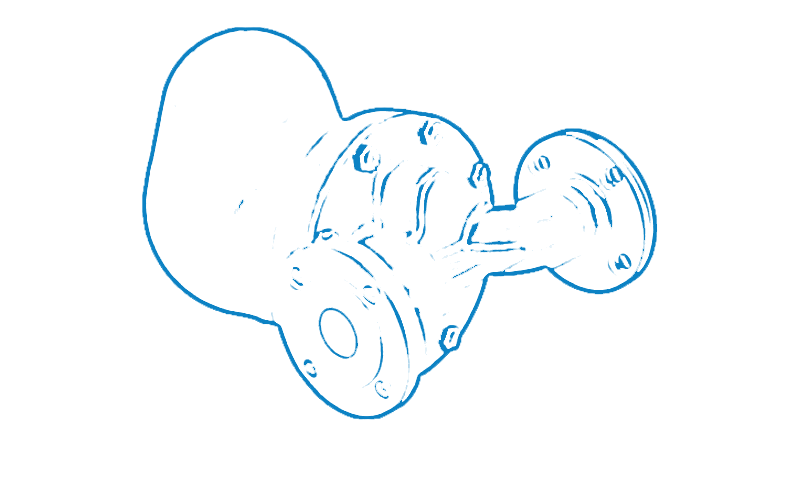

Thermo static floating ball trap

CS41H thermostatic free ball float steam trap is an automatic valve, especially for the steam equipment with low pressure, low displacement and high temperature stability requirements, which is not suitable for the storage of condensed water.The main working principle of free float steam trap is to make the float ball in the valve body rise and fall with the change of water level according to the principle of buoyancy, so as to achieve the opening and closing of the valve, that is, the effect of steam drainage.Widely used in all kinds of steam pipeline.

Structural features

1. Continuous drainage, stable performance, large displacement and small leakage.

2. Continuous saturated water can be discharged to make the equipment condensate stagnant stock less, fast heating and stable heating temperature.

3. Automatic exhaust cold air device, no steam lock phenomenon, work balance without noise.

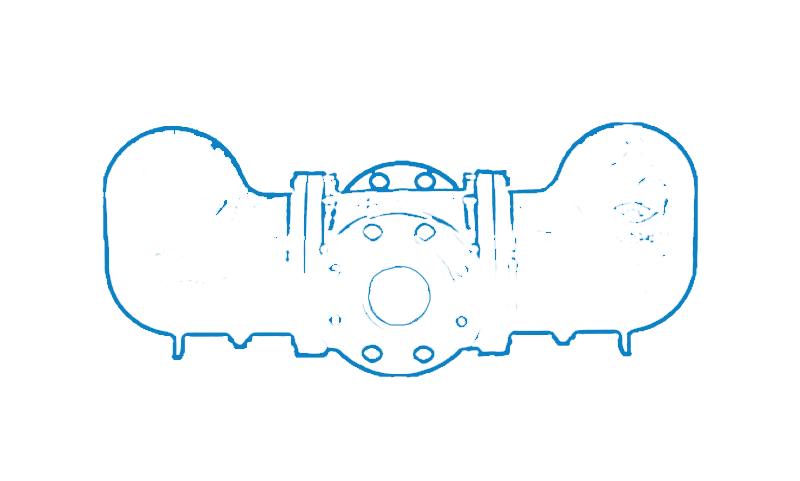

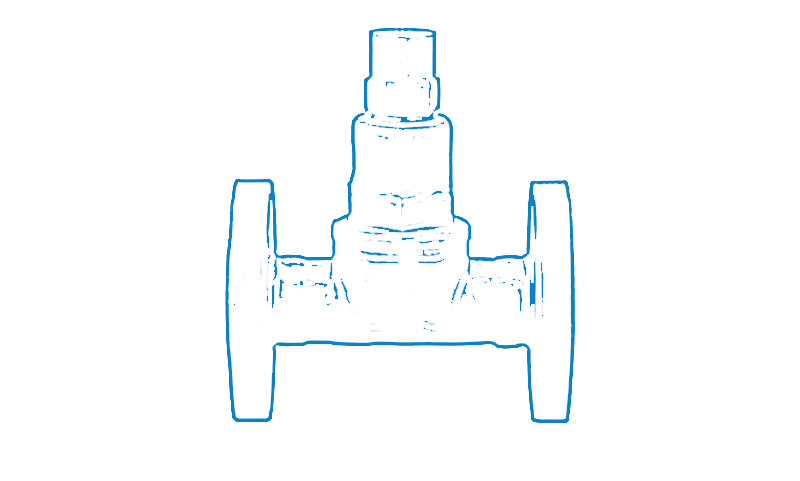

Rod floating ball valve

The rod-bar type floating ball valve is widely used in petrochemical, metallurgy, paper making, food and other industrial steam equipment, dryer and various large heat exchangers, especially suitable for the large displacement of condensate water work field and.

Double balance bar

Lever ball float steam trap is used in steam heating equipment, condensate water recovery system and the condition that the condensate water needs to be quickly discharged. It can automatically, rapidly and continuously discharge the condensate water, effectively prevent the steam leakage and obtain a better heating effect.

Product features

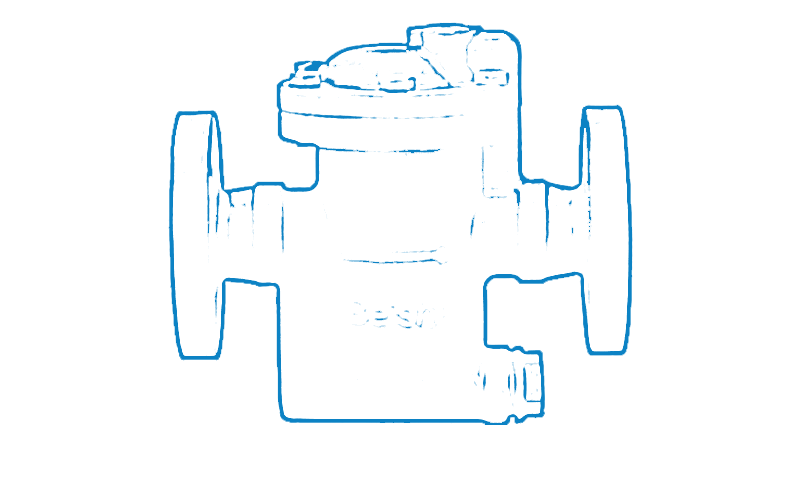

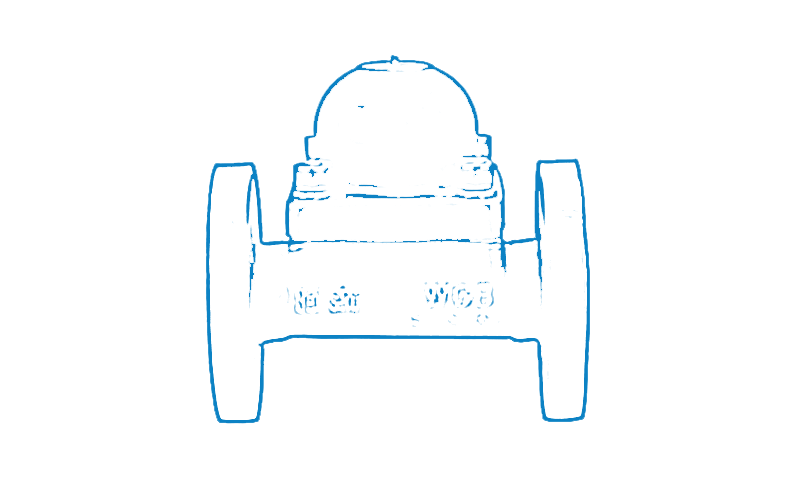

Inverted bucket trap

The opening and closing of the inverted bucket steam trap is based on the density of condensed water and steam and to the action, its action is accurate and reliable.

Product features

Inverted bucket pilot steam trap

Inverted bucket pilot steam trap adopts top type structure, under high pressure, large diameter conditions to reduce the connecting bolt of the valve body itself, enhance the reliability of the valve and overcome the system weight on the normal operation of the valve.

technical parameter

Nominal diameter: DN50mm-DN300mm;

Nominal pressure: PN1.0Mpa - 1.6Mpa;

Temperature range: -29℃-300℃.

Adjustable bimetal

Working principle of TB6 bimetal temperature-adjusting type: the valve deforms the temperature sensing bimetal steam according to the change of temperature, and then drives the valve core to act as the main compound shift to open and close the valve seat hole, so as to prevent steam discharge.

Technical parameter

Bimetallic thermostat

Working principle of bimetallic temperature-adjusting type: the valve causes the deformation of bimetallic vapour sensing temperature according to the change of temperature, thus driving the valve core as the main complex shift opening and closing the valve seat hole, to achieve the steam emission resistance.

Technical parameter

Steam vertical bellows screw trap

According to the temperature change in the valve cavity is the bellows in the temperature sensing liquid vaporization or condensation, bellows internal pressure changes and drive the bellows to drive the spool as a shift opening and closing valve seat hole, to achieve steam resistance and drainage.The valve is widely used in practical, energy saving and environmental protection. It is one of the best heat traps for steam main line in heating flow, small heating equipment and material heat tracing in petrochemical industry, and valve material heat tracing.

Product features

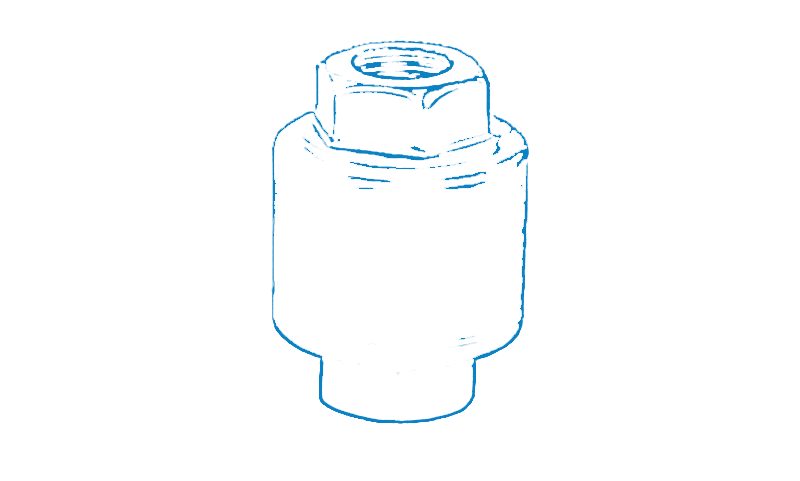

Thermostatic bellows

CS16 thermostatic bellows (steam pressure balance type) is an energy saving trap in common use.The reaction of the bellows steam trap is very sensitive, there is high temperature condensate water in front of the valve when working, no steam leakage, and the energy saving effect is remarkable.Its advantages are: automatic air exhaust, small volume, not afraid of cold, any position can be installed;Convenient maintenance, in the pipeline can be checked to repair and replace parts;Back pressure rate ≤80%, solid film box, long service life.

Technical parameter

Product model: CS16

Nominal diameter: DN15~50mm

Nominal pressure: PN0.05-1.6MPa

Operating temperature: ≤350℃

Main material: forged steel, stainless steel, titanium alloy steel, chromium molybdenum steel, low temperature steel

Drive mode: manual

Thermostatic bellowst

CS46 Thermostatic membrane box type working principle: the valve according to the temperature changes in the chamber is the bellows in the temperature of the liquid vaporization or condensation, bellows internal pressure changes and drive the bellows to drive the valve core as a shift opening and closing valve seat hole, to achieve steam resistance and drainage.

Technical parameter