Copyright © Luohe (Wuxi) fluid control Co., Ltd All rights reserved.

ICP2021014876

Copyright © Luohe (Wuxi) fluid control Co., Ltd All rights reserved.

ICP2021014876

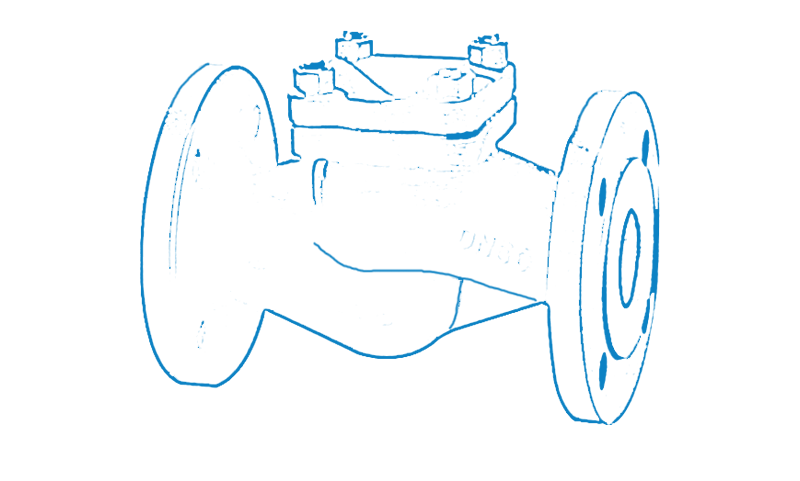

DIN lift check valve

When the medium by the valve body arrow flow into the valve body, the pressure of the medium on the disc to produce upward thrust, when the medium thrust is greater than the gravity of the disc, check valve open.When the valve after the medium pressure acting on the force on the disc plus the gravity of the disc itself is greater than the pressure before the valve acting on the force on the disc, the check valve is closed to prevent the medium from flowing back.

Structural features

1. DIN lifting check valve products reasonable structure, reliable sealing, excellent performance, beautiful appearance;

2. Sealing surface surfacing CO cemented carbide, wear resistance, corrosion resistance, good resistance to friction, long service life;

3. Valve stem quenching and surface nitriding treatment, with good anti-corrosion and anti-friction properties;

4. Double sealing, more reliable performance;

5. Stem lifting position indication is more intuitive;

6. Parts materials, flange and butt-welding size can be reasonably selected according to actual working conditions or user requirements to meet various engineering needs.

Cast iron soft seal check valve

Cast iron soft seal check valve is generally suitable for normal temperature and pressure, medium is water, ordinary gas and non-corrosive liquid and other conditions of one-way flow in the pipeline, widely used in building system, water treatment system, fire pipe, municipal, mining equipment, water plant, engineering construction and other fields to prevent the reverse flow of the medium.

Product features

Reliable sealing;

Agility;

Small resistance;

Reduce water hammer pressure;

Suitable for large and medium caliber pipeline;

Horizontal and vertical installation;

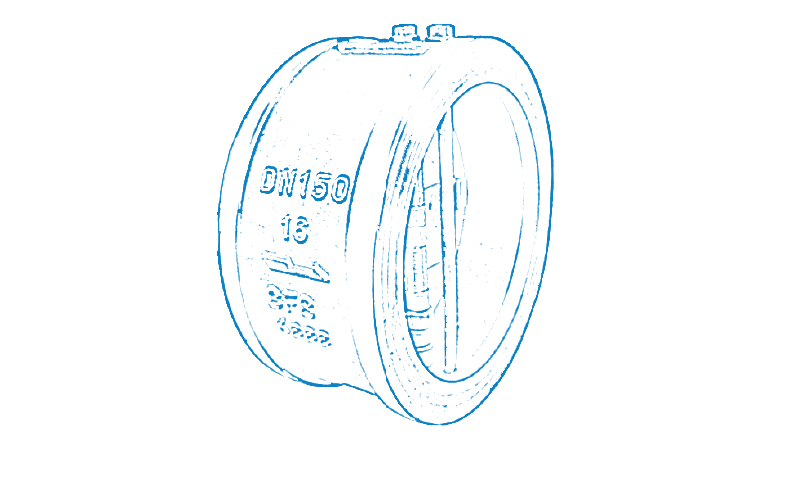

Wafer ultra thin check valve

The wafer type ultra-thin return valve is a kind of disc type ultra-thin return valve. It adopts short structure ruler and single disc design. The disc is attached with O-ring, with good sealing performance and spring assisted closing. It is sensitive to action, especially suitable for places with limited installation space. The utility model has the advantages of simple structure, beautiful appearance, light weight, convenient installation, etc. It is mainly suitable for water supply system, oil, chemical industry, metallurgy and other fields.

Structural features

Wafer lift check valve

Wafer lift check valve is suitable for pressure PNL.0~16.0MPa.Operating temperature -196-425¡æ of various conditions on the pipeline.Prevent the backflow of the medium.

Product features

Wafer lift check valve

The Wafer lift check valve is suitable for pressure PNL.0~16.0MPa.Operating temperature -196-425¡æ of various conditions on the pipeline.Prevent the backflow of the medium.

Product features